1.Solution preparation:

(1)Dispersed phase: 5%(wt%) chitosan solution:

0.5 g of chitosan, 9.3 g of pure water and 0.2 g of glacial acetic acid are mixed homogeneously and heated to 85℃. After dissolved completely, filter the solution with a 0.22 μm syringe tip filter.

(2) Cross-linking reagent solution: 1% glutaraldehyde solution in oil:

10 μL of 50% glutaraldehyde solution and 490 μL of Drop-Surf Droplet Generation Oil are mixed homogeneously with vortex to obtain a 1% glutaraldehyde solution.

2. Preparation of microdroplets:

(1) Microfluidic devices set-up

For a more detailed installation and connection of Microdroplet/Microsphere Generator, refer to the User Guide V.1.0 Of Microdroplet/Microsphere Generator, section 2. Installation and connection of Microdroplet/Microsphere Generator. The connection is as follows (steps③-⑦ are shown in the figure below):

① Connect the devices with PU tubing in the following order:

The air compressor–the air source processing device–the Microdroplet/Microsphere Generator

② Connect the device to the power supply and PC, respectively.

③ Connect A0 (the pressure channel 1 outlet) and A1 (the continuous phase reservoir), B0 (the pressure channel 2 outlet) and B1 (the dispersed phase reservoir) with PU tubing, respectively;

④ Connect A1 (the continuous phase reservoir) and A2 (the flow sensor channel 1 ), B1 (the dispersed phase reservoir) and B2 (the flow sensor channel 2) with PEEK tubing and 1/4-28 UNF, respectively;

⑤ Connect A2 (the flow sensor channel 1) and A3 (the continuous phase inlet of the PDMS chip), B2 (the flow sensor channel 2 ) and B3 (the dispersed phase inlet of the PDMS chip) with PEEK tubing and 1/4-28 UNF, respectively ;

⑥ C is a combination of a PDMS standard chip and a chip holder, which is sealed by 6 silicone connector seals;

⑦ The PEEK tubing is inserted into the chip & chip holder outlet (D) for emulsion output.

(2) Installing FluidicLabSuite software:

Refer to the section 3.1 Installation of FluidicLabSuite Software in the User Manual V.1.0 Of Microdroplet/Microsphere Generator;

(3) Preparation of chitosan microdroplets:

For a visualized guide of this section, refer to Application Video: Preparation of Chitosan Microspheres by Microdroplets Generator.

① 5 mL of Drop-Surf Droplet Generation Oil and 1 mL of 5% chitosan aqueous phase solution are added into the corresponding reservoirs, respectively:

1.Reservoir 1 (controlled by Pressure Channel 1): Droplet Generation Oil;

2.Reservoir 2 (controlled by Pressure Channel 2): 5% chitosan aqueous phase.

② For the use of the camera and the flow sensors, refer to the section 3.2 Equipment Addition of FluidicLabSuite Software in the User Guide V.1.0 Of Microdroplet/Microsphere Generator.

③ Turn on the air compressor and air source treatment device.

④ A Centrifuge tube is placed at the emulsion outlet to collect the pre-waste liquid.

⑤ Set the pressure of pressure channel 1 and 2 by FluidicLabSuite control to exhaust the air in the PEEK tubing and the microchannels of chip.

Tips: Due to its high viscosity, we kindly suggest you set a higher pressure in the dispersed phase than in the continuous phase. For example:

Pressure Channel 1 (controlling the continuous phase): 150 mbar;

Pressure Channel 2 (controlling the dispersed phase): 900 mbar.

⑥ After the PEEK tubing and the microchannel of chip are filled with liquid, switch the control mode from pressure control to flow rate control. The flow rates of channels 1 and 2 are set as 20 and 5 μL/min, respectively.

⑦ The smooth output of target flow rate can be quickly achieved through adjusting the feedback value.

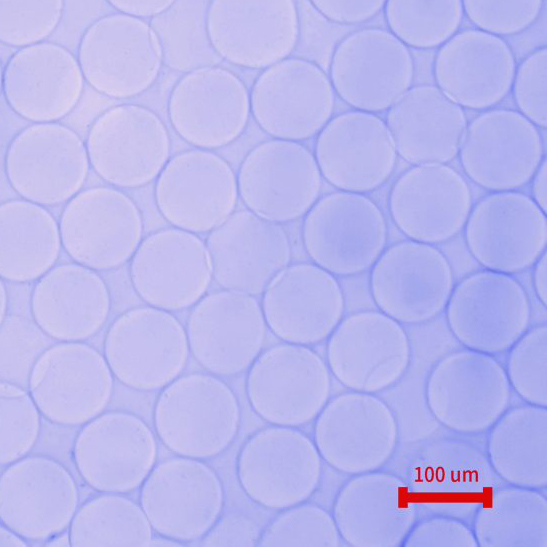

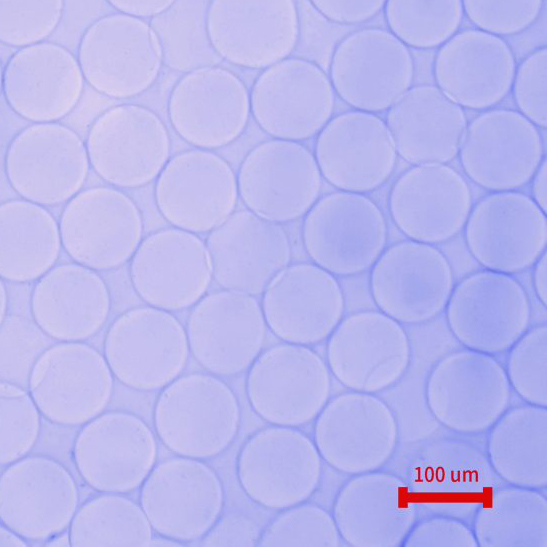

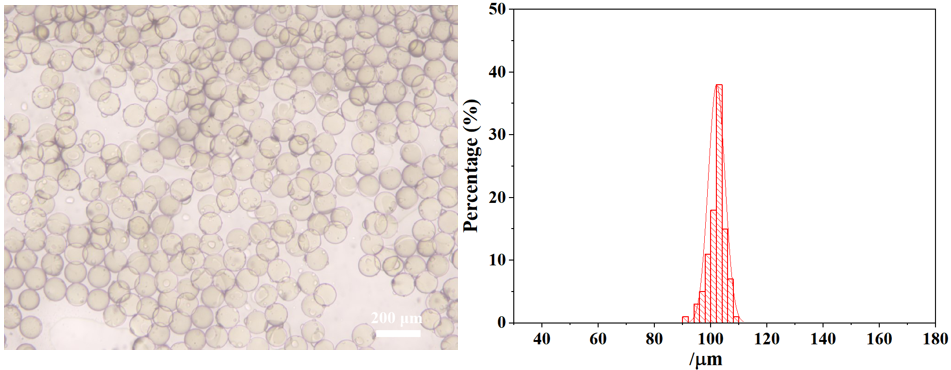

⑧ After a few minutes, collect a drop of the emulsion onto a hydrophobic substrate base, and ensure the uniformity of droplet size with an optical microscope.

⑨ After that, collect the emulsion into a 1.5 mL Centrifuge tube containing cross-linking reagent solution.

⑩ Collect the emulsion for 20 minutes, and 20 minutes of cross-linking time with gently vibration is allowed for cross-linking gelation.

3. Aftertreatments:

For a visualized guide of this section, refer to Application Video: Preparation of Chitosan Microspheres by Microdroplets Generator.

① Remove the oil phase (at the bottom of the tube) with a pipette;

② Add 2x volume of Drop-Surf Demulsifier to the microspheres. For every 100 μL microspheres, add 200 μL Drop-Surf Demulsifier.

③ Vortex the mixture for 20 seconds, then centrifuge 2000 rpm for 30 seconds. Remove the demulsifier at the bottom of the container.

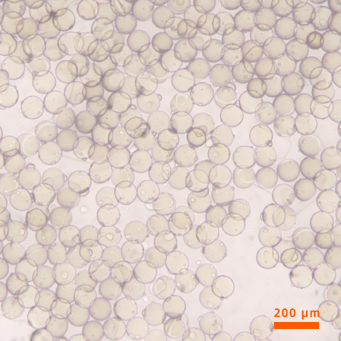

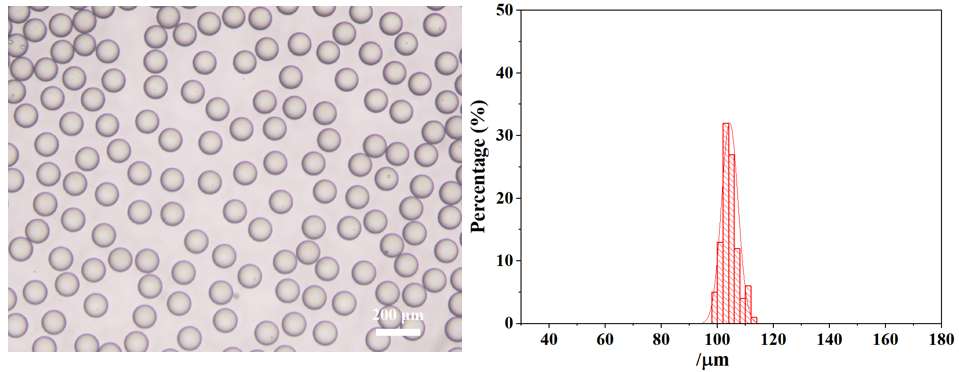

④ Repeat steps ② and ③ 1~2 times. Finally, the solidified chitosan microspheres are obtained.

Tips: It is not recommended to disperse prepared chitosan hydrogel microspheres in water since the microspheres may swell and dissolve.

4. Cleaning of Microdroplets/Microsphere of Generator:

The PEEK Tubing, the flow sensors and the microchannels of the chip in the instrument should be cleaned after the experiment. Otherwise, the reagents remaining in the flow channels could possibly damage the flow sensors and clog the microchannels of the chip. For details, please refer to the Instruction Card of Microdroplet/Microsphere Generator.