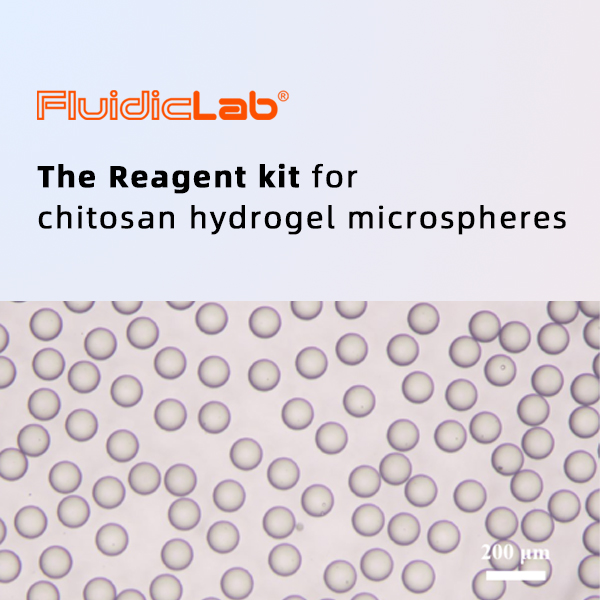

FluidicLab Reagent kit for chitosan hydrogel microspheres

FluidicLab provides a full kit for preparation of chitosan hydrogel microspheres. This kit is composed of the aqueous phase (5% chitosan aqueous solution with 2% acetic acid), the oil phase (Drop-Surf Droplet Generation Oil), the cross-linking reagent (50% glutaraldehyde) and the aftertreatment reagent (Drop-Surf Demulsifier).

To reach a desired result of highly monodisperse chitosan hydrogel microspheres (CV<5%), we strongly recommend you to use FluidicLab Microdroplet Generator and FluidicLab Microfluidic Chips (hydrophobic, with a chip holder). For further information, refer to related introductions.

The dispersed phase and the continuous phase are pushed into a microfluidic chip by FluidicLab Microdroplet Generator, and droplets are generated after the dispersed phases sheared by the continuous phase. The Schiff’s base reaction between glutaraldehyde and chitosan begins when the emulsion of chitosan microdroplets is dropped into a solution containing glutaraldehyde.

Room temperature; sealed.

1.Solutions preparation

- a. Cross-linking reagent solution

- 10 μL of 50% glutaraldehyde solution and 490 μL of Drop-Surf Droplet Generation Oil are mixed homogeneously with vortex to obtain a 1% glutaraldehyde solution.

- Tips: a higher concentration of glutaraldehyde is more favorable for the Schiff’s base reaction.

- b. b.Fill the reservoirs and the collection container with prepared solutions.

- Reservoir 1 (controlled by Pressure Channel 1): Droplet Generation Oil;

- Reservoir 2 (controlled by Pressure Channel 2): Aqueous phase;

- Collection container: 1% cross-linking reagent solution.

2.Preparation of chitosan hydrogel microspheres

- a. Microfluidic devices set-up

- Refer to instructions to Microdroplet Generator.

- Standard PDMS-FF-50 chips and PDMS-FF-100 chips are recommended.

- b. Generation of the microdroplets

- 1). The oil phase solution and aqueous phase solution are respectively introduced into the microfluidic chip by pressure.

- 2). Set proper flow rates in order to reach a stable microdroplet generation.

- For example

Chip: Standard PDMS-FF-100 Chip

Channel 1 (oil phase): 20 μL/min

Channel 2 (Aqueous phase): 5 μL/min

Tips: For Standard PDMS-FF-50 Chips, the flow rates should be lower due to its narrower channel. The diameter of hydrogel microspheres is determined by the type of the chip and the flow rate ratio of both phases.

- 3). The droplets can be collected in a hydrophobic container with the cross-linking reagent solution when the droplets size in the emulsion are homogeneous.

- c. Cross-linking gelation

- Once the droplets are collected, 20 minutes of cross-linking time with gently vibration is allowed for cross-linking gelation.

- d. Aftertreatments

- 1) Remove the oil phase (at the bottom of the container) with a pipette;

- 2) Add 2x volume of Drop-Surf Demulsifier to the microspheres. For every 100 μL microspheres, add 200 μL Drop-Surf Demulsifier.

- 3) Vortex the mixture for 20 seconds, then centrifuge the mixture at 2500 rpm for 60 seconds. Remove Drop-Surf Demulsifier at the bottom of the container.

- 4) Repeat steps 2) and 3) 1~2 times.

- Tips: It is not recommended to disperse prepared chitosan hydrogel microspheres in water since the microspheres may swell and dissolve.