FluidicLab Reagent kit for alginate hydrogel microspheres

FluidicLab provides a full kit for preparation of alginate hydrogel microspheres. This kit is composed of the aqueous phase (including alginate sodium solution, Ca-EDTA chelate solution, Zn-EDDA chelate solution), the oil phase (Drop-Surf Droplet Generation Oil) and the aftertreatment reagents (including Drop-Surf Demulsifier and PBS buffer).

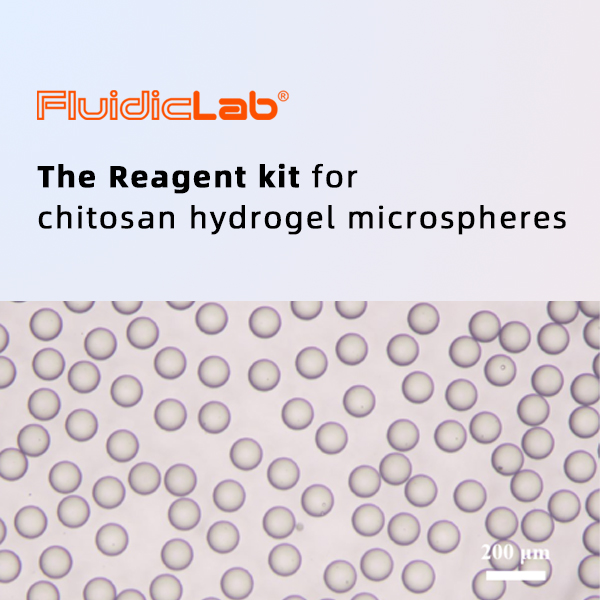

To reach a desired result of highly monodisperse alginate hydrogel microspheres (CV<5%), we strongly recommend you to use FluidicLab Microdroplet Generator and FluidicLab Microfluidic Chips (hydrophobic, with a chip holder). For further information, refer to related introductions.

The dispersed phase 1 (containing Ca-EDTA chelate and sodium alginate), the dispersed phase 2 (containing Zn-EDDA chelate and sodium alginate) and the continuous phase (Drop-Surf Droplet Generation Oil) are pushed into a microfluidic chip by FluidicLab Microdroplet Generator, and droplets are generated after the dispersed phases mixed together and sheared by the continuous phase. Once two dispersed phases are mixed, the Zn2+ binds with EDTA due to its affinity with different ligands, resulting in release of Ca2+ which subsequently cross-links the alginate.

1.Solutions preparation

- a. Dispersed phase 1: a mixture of an equal volume of sodium alginate solution and Ca-EDTA solution (40mM, pH=6.7);

- b. Dispersed phase 2: a mixture of an equal volume of sodium alginate solution and Zn-EDDA solution (40mM, pH=6.7);

- c. The prepared dispersed phases should be filtered through 0.22 μm or 0.45 μm filter membrane.

- d. Fill the reservoirs with prepared solutions.

Reservoir 1 (controlled by Pressure Channel 1): continuous phase ;

Reservoir 2 (controlled by Pressure Channel 2): dispersed phase 1;

Reservoir 3 (controlled by Pressure Channel 3): dispersed phase 2.

2.Preparation of alginate hydrogel microspheres

- a. Microfluidic devices set-up

- Refer to instructions to Microdroplet Generator.

- Standard PDMS-SCE-30 Chip, PDMS-SCE-50 Chip and PDMS-SCE-100 Chip are recommended.

- b. Generation of the microdroplets

- 1). The continuous phase, dispersed phase 1 and dispersed phase 2 solution are respectively introduced into the microfluidic chip by pressure.

- 2). Set proper flow rates in order to reach a stable microdroplet generation. The flow rate of dispersed phase 1 (Channel 2) should be the same as that of dispersed phase 2 (Channel 3).

- For example

Chip: Standard PDMS-SCE-100 Chip

Channel 1 (oil phase): 20 μL/min

Channel 2 (dispersed phase 1): 5 μL/min

Channel 3 (dispersed phase 2): 5 μL/min

Tips: For Standard PDMS-SCE-50 Chips, the flow rates should be lower due to its narrower channel. The diameter of alginate hydrogel microspheres will be determined by the type of chip and the flow rate ratio of all phases.

- 3). The droplets are collected in a container when the droplets size in the emulsion are homogeneous.

- c. Cross-linking gelation

- Once the droplets were collected, 10 minutes of cross-linking time was allowed for cross-linking gelation.

- d. Aftertreatments

- 1) Remove the oil phase (at the bottom of the container) with a pipette;

- 2) Add 2x volume of Drop-Surf Demulsifier to the microspheres. For every 100 μL microspheres, add 200 μL Drop-Surf Demulsifier.

- 3) Vortex the mixture for 20 seconds, then centrifuge 1000 rpm for 30 seconds. Remove Drop-Surf Demulsifier at the bottom of the container.

- 4) Repeat steps 2) and 3) 1~2 times, until all white microspheres on the top of the container change into transparent.

- 5) Add 3x volume of PBS buffer to the microspheres. For every 100 μL microspheres, add 300 μL PBS buffer.

- 6) Vortex the mixture for 20 seconds, then centrifuge 1000 rpm for 120 seconds. Remove PBS buffer at the upper of the container.

- 7) Repeat steps 5) and 6) 1~2 times

- 8) Finally, disperse the microspheres in a PBS buffer.